If you are planning to import Neodymium magnets from abroad, you have various options.

But the quickest and most convenient long-distance way to transport magnets is by air.

This method involves some risks, as magnetic fields can interfere with flight performance.

Thus there are international regulations and guidelines in place to avoid safety issues.

But the good news is that the safe transport of Neodymium magnets is possible.

The way to do this is through the process of magnetic shielding.

This blog post will show you how we ensure our magnets’ quick, safe and compliant transport.

We hope it will put your mind at ease when dealing with this sensitive safety issue.

The usual way by which we send our magnets across is via International Express.

We prefer this because we value the time of those who buy from us.

This arrangement allows customers to get their items within a matter of a handful of days.

Neodymium magnets can disturb airplane equipment, particularly the parts related to navigation.

These may include GPS displays, high-frequency radios, and landing systems.

Using this equipment allows air traffic controllers to communicate with pilots and staff.

The design of the instruments occurs with the Earth’s magnetic field in mind.

And so, the presence of Neodymium magnets can impact their functionality.

Any deviation in the planned path of a plane is hazardous, so constant tracking is necessary.

Also, magnets may impact the many electronic devices aboard air carriers.

Cargo delivered via air is often quite expensive, so financial losses can be steep if things go wrong.

Not to mention the far worse possibility of a loss of human life and the value of the plane itself.

When it comes to shipping Neodymium magnets via air, precise protocols are in place.

Delivery must be in line with the International Air Transport Association’s Guidelines.

These guidelines differentiate dangerous goods from safe ones.

In the context of magnets, a dangerous good is one with a magnetic flux of 0.00525 Gauss or higher.

This number applies to the magnet at a distance of seven feet from it in all directions.

Another way to check is to observe the deflection of a compass needle in the vicinity of a magnet.

If the deflection is more than 2-degrees in any direction, the magnet presents a risk.

And Neodymium magnetic fields are much stronger than those of other magnets.

So meeting these standards is mandatory to ensure flight safety.

Blocking magnetic fields is the way to ensure compliance with air transport standards.

We usually achieve this by using steel plates.

But we cannot place the magnets openly within a container with a lining made of steel plates.

The magnets must also reach customers free of damage, and they should use them safely.

So our approach to packaging combines meeting air transport requirements with customer convenience.

A vital part of this effort is to ensure that magnets don’t stick together, which can damage their edges.

Plus, detaching them may be difficult and risks physical injury as well.

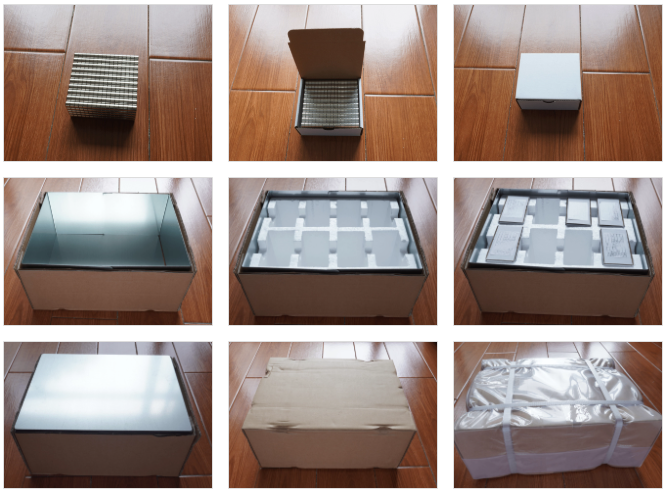

So we place individual magnets inside separate boxes.

These are then placed inside a foam container with individual spaces for up to 8 boxes.

The spaces are of the exact size of each magnet box, so there is no risk of movements in the flight that may damage them.

This step also keeps the magnets well apart.

Then comes the time to put in the steel plates to block magnetic fields.

Here, we first line up the plates along the four sides and the base of a carton.

The size of this carton (with the plates put in) is such that the foam box in the previous step fits into it perfectly.

Another steel sheet is put on top to complete the blocking process (steel sheets now cover all six sides).

The carton is then closed and is finally ready for shipping.

Airlines and logistics firms want flights with magnetic materials aboard to go smoothly.

To achieve this, they ask shippers for an Air Transport Conditions Identification Report.

So the shipper must take the packages to an appointed institute for magnetic testing.

In general, only a qualified professional appraisal company can issue air transport appraisals.

And the Civil Aviation Administration must recognize such a company.

Furthermore, each shipment must undergo a separate test.

Magnetic inspection requires customers to pack the goods according to air transportation requirements.

The inspection itself won’t cause any damage to the packaging of the goods.

In principle, the goods wouldn’t even be opened during the inspection.

The process only detects stray magnetic fields on the six sides of each box.

Special attention is necessary in case the magnetic inspection of a package fails.

In such a situation, the packages are sent back to the shipper for repacking.

Or an alternative is for the relevant department of the testing agency to do the repackaging.

In this scenario, the shippers will pay the related fees.

We deliver Neodymium magnets to customers using the fastest route (via International Express).

Customer satisfaction is essential to us.

We guarantee the undamaged, compliant and timely delivery of our magnets.

And we do it with great care to meet all air transport requirements needed for flight safety.

Our priority is to clear all relevant tests in the first attempt to avoid the hassle of repackaging.

Therefore, we ensure our packaging completely blocks any magnetic interference of flight equipment.

For this, we have a well-trained, dedicated team of professionals in place.

This team takes up all the necessary tasks involved for smooth delivery.

It ensures error-free packaging and takes care of any required documentation.

In short, we leave no stones unturned in getting you the products you desire safely and speedily.

Direct Solution for Your Production &

Need A Quote?

❶ Technical Specifications ❷ Real-Time Inventory ❸ Instant Quotation